Submersible pumps are essential devices in various sectors, from residential to industrial applications. With the ability to operate underwater and deliver high performance, submersible pumps are increasingly becoming the preferred choice for many users. In this article, Siam Brothers Vietnam will explore the concept, structure, advantages and disadvantages, key factors to consider when choosing a submersible pump, and where to buy one from a reputable source.

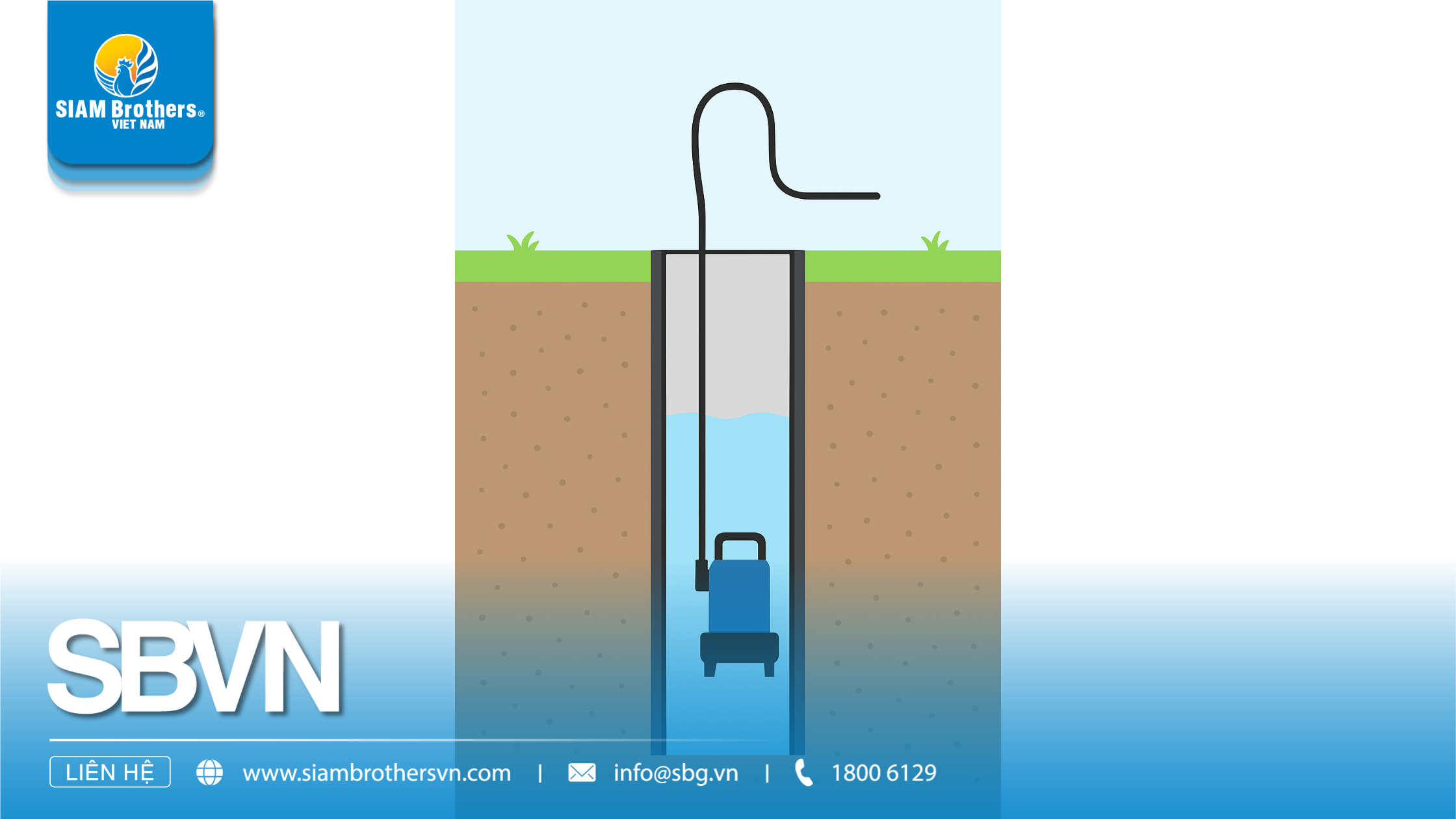

Source: SIAM Brothers Vietnam

A submersible pump is designed to be fully submerged in the liquid it is pumping. The motor is protected by a waterproof casing, ensuring safe and durable operation. Submersible pumps are widely used for water supply and drainage, wastewater treatment, irrigation, groundwater extraction, and many other applications.

Structure and operating principle of submersible pumps – Source: SIAM Brothers Vietnam

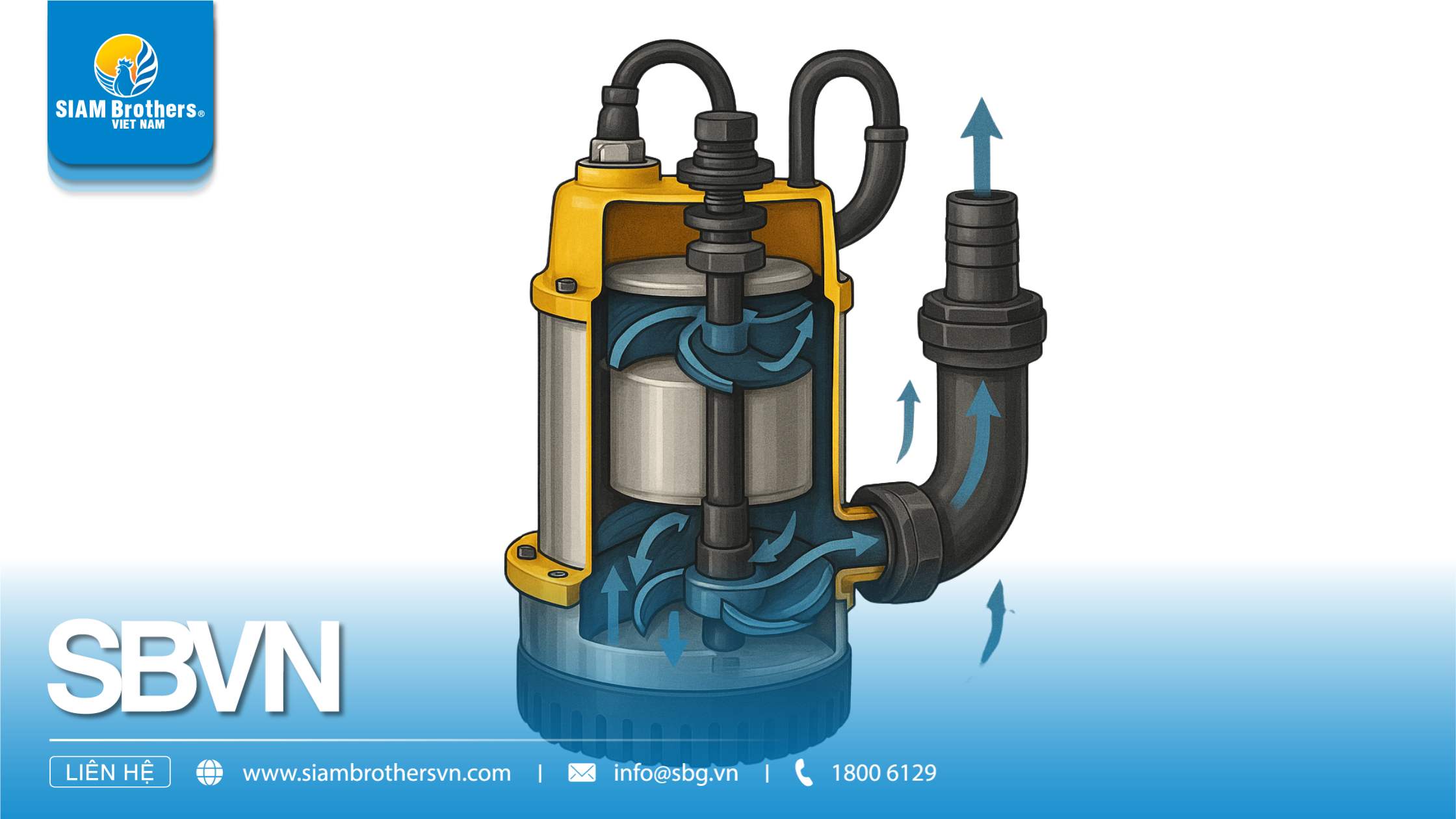

The basic components of a submersible pump include:

Electric motor enclosed and waterproofed.

Impeller or working wheel that generates fluid movement.

Pump shaft connecting the motor to the impeller.

Pump casing made from stainless steel, cast iron, or plastic, depending on the working environment.

Mechanical seal system to prevent leakage.

Working principle: When the motor rotates, the impeller generates centrifugal force or pressure to push the liquid upward through the discharge pipe. Because the entire pump is submerged, it does not require priming like surface pumps and is less prone to cavitation.

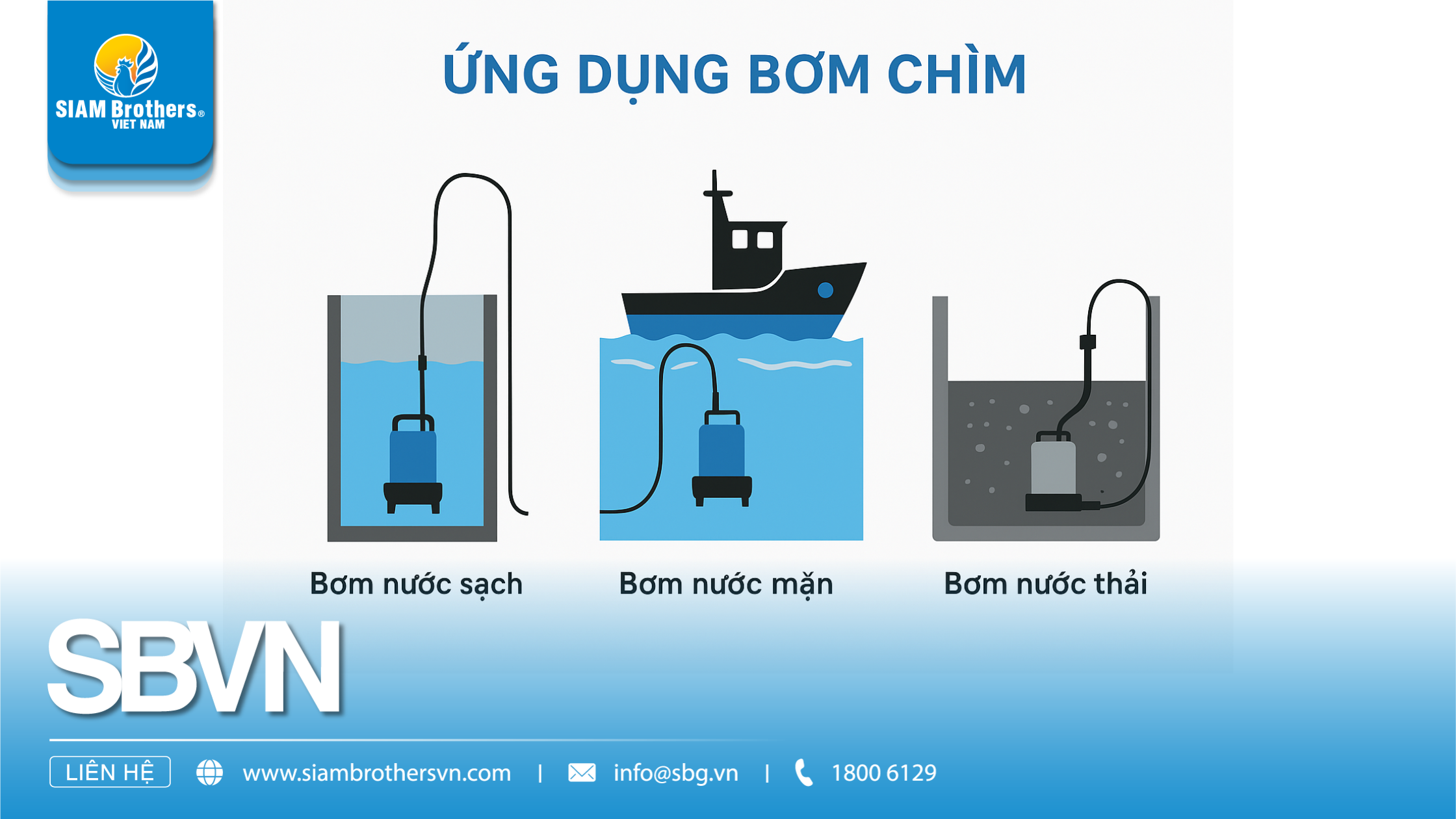

Clean water submersible pumps – For households, water tanks, shallow wells.

Borehole submersible pumps – Designed for extracting water from great depths.

Wastewater submersible pumps – Capable of handling liquids mixed with debris or solids.

Industrial submersible pumps – High-capacity pumps for large-scale production and wastewater treatment.

Slurry/sand submersible pumps – For mining, dredging rivers and lakes.

Common types of submersible pumps – Source: SIAM Brothers Vietnam

Quiet operation with minimal vibration.

No priming required before pumping.

High efficiency with no suction loss.

Space-saving installation.

Can pump from great depths.

Difficult to inspect and repair when problems occur.

Higher cost compared to some other pump types.

Requires a stable power supply and must not run dry.

When choosing a submersible pump, don’t just focus on price — you also need to consider technical specifications to ensure the pump operates efficiently, lasts longer, and fits your specific needs.

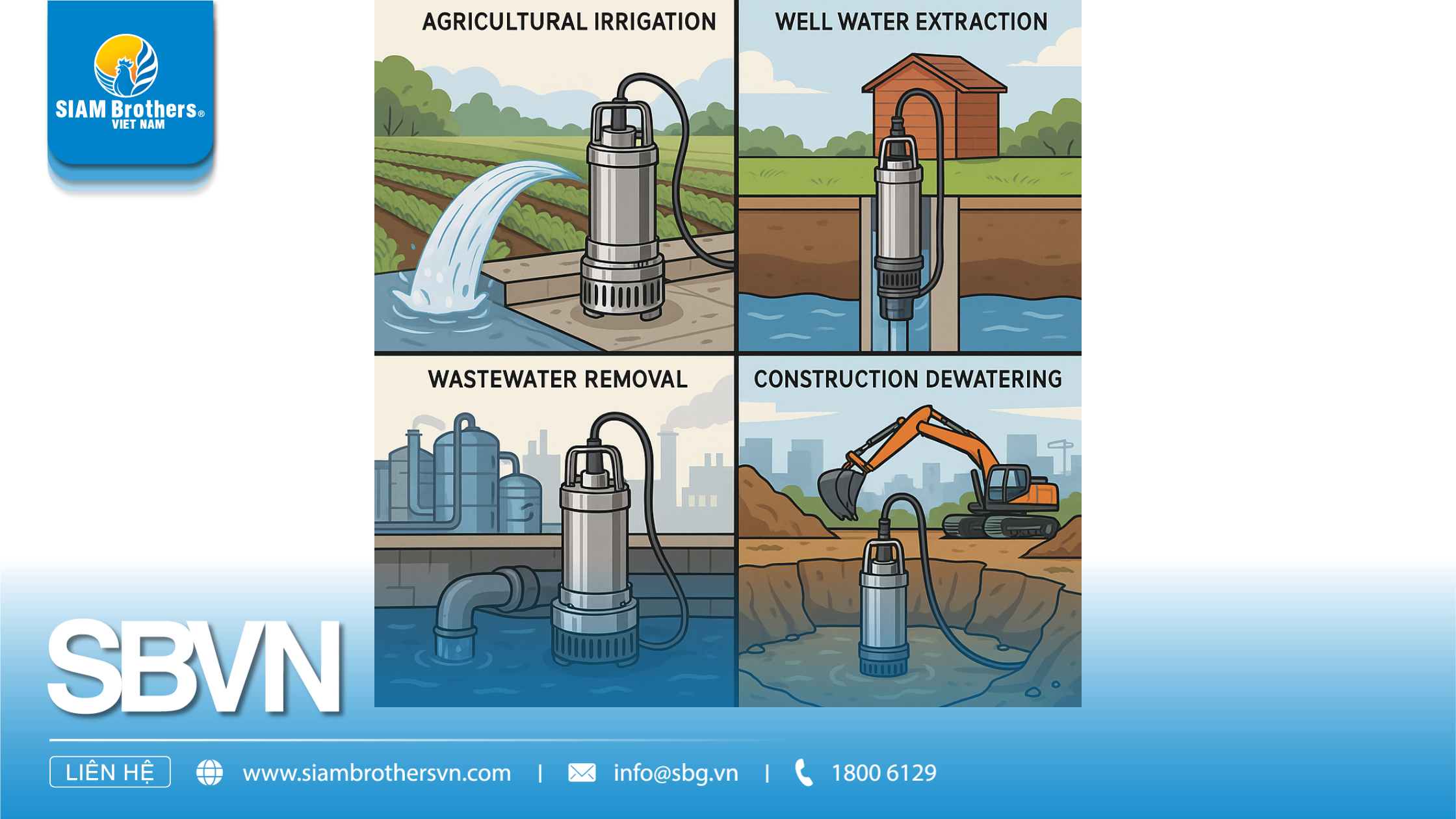

Defining your purpose will help you choose the right pump:

Clean water pumping: Suitable for boreholes, water tanks, or household water supply.

Wastewater pumping: For handling water from drainage systems, factories, or septic tanks.

Slurry pumping: For construction sites, dredging, or mining.

Deep well pumping: Designed for high-pressure operation at great depths.

Applications of submersible pumps – Source: SIAM Brothers Vietnam

Two of the most important technical parameters:

Flow rate: The amount of water the pump can move in a given time (m³/h).

Head (total head): The maximum height the pump can push water. Choosing the wrong head will reduce efficiency or cause damage.

Material determines durability and environmental resistance:

Stainless steel: Excellent corrosion resistance, ideal for saline or acidic water.

Cast iron: Extremely durable and impact-resistant, suitable for wastewater and slurry.

Engineering plastic: Lightweight, affordable, suitable for light-duty household use.

Single-phase (220V): For households and small-scale projects.

Three-phase (380V): For industrial and large-scale agricultural systems.

If the pump is for wastewater or slurry, check the maximum solid particle size it can handle to prevent clogging or impeller damage.

Choosing a reputable brand ensures quality and provides peace of mind regarding warranty, spare parts, and technical support.

When buying a submersible pump, the key factor is not just price or brand — it’s choosing one that fits your actual usage. Different environments and purposes require different capacities, materials, and features.

At Siam Brothers Vietnam, you can easily find a pump that meets your needs, including:

Submersible Pump BP‑12V‑50W - Source: SIAM Brothers Vietnam

If you only need to pump water from ponds, tanks, fish ponds, or for temporary work, prioritize portability and energy efficiency:

=> BP 12V 50W – Compact, easy to move, suitable for clean water or rainwater from tanks.

=> BPS 12V 120W – Higher capacity, suitable for households or continuous pumping with moderate flow rates.

In environments with frequent movement requiring DC power, the pump must handle vibration well and operate reliably:

=> BPS 24V 180W – Ideal for water supply/drainage on tourist boats, canoes, or mobile pump systems using 24V DC power.

For coastal areas, aquaculture, or salt production, corrosion resistance is crucial:

=> SSS1.5-16 370W stainless steel pump – Full stainless steel body, resistant to saltwater and brackish water, long lifespan.

SSS1.5-16-0.37-370W Stainless Steel Submersible Pump - Source: SIAM Brothers Vietnam

When large flow rates and quick drainage are required:

=> SSS10-10 550W stainless steel pump – Corrosion-resistant and powerful, suitable for aquaculture farms, livestock farms, or factories.

=> SWQD 1500W – Extremely high power, designed for industrial environments, construction sites, and emergency drainage.

High-Power Submersible Pump SWQD-3” – 1500W - Source: SIAM Brothers Vietnam

Tip: Clearly define your needs (water type, power supply, required flow rate, usage frequency) before purchase. This not only saves initial investment costs but also extends the pump’s lifespan.

Q1: Do submersible pumps consume a lot of electricity?

→ It depends on capacity; household models typically consume 0.5 – 1.5 kWh per hour.

Q2: Can I use a submersible pump for hot water?

→ Only certain high-temperature models can — always check specifications.

Q3: Do submersible pumps require maintenance?

→ Yes, regular cleaning every 6 months is recommended.

Q4: Can a submersible pump run dry?

→ No — running dry can burn out the motor.

Source: SIAM Brothers Vietnam

Contact us:

Address: 5th floor, VRG Building, 177 Hai Ba Trung Street., Vo Thi Sau Ward, District. 12, Ho Chi Minh City, Vietnam

Tel: (+84) 28 38 912 889

Hotline: 1800 6129

Facebook: www.facebook.com/siambrothersvn

Email: info@sbg.vn

YouTube: youtube.com/@siambrothersvietnam1728

OA Zalo: zalo.me/1402339229697925373

App SBVN ID:

CHPlay: https://bit.ly/SBVNID-Android

Appstore: https://bit.ly/SBVNID-iOS