8-strand rope splicing is not only an essential technique to enhance durability and safety for fishing vessels but also a critical skill every fisherman should master before heading offshore. A properly executed splice strengthens the rope’s load-bearing capacity, prevents slippage in rough seas, and helps reduce the cost of frequent replacements. This article provides a step-by-step guide to 8-strand rope splicing, complete with illustrated images, video instructions, and a quick checklist. Join SIAM Brothers Vietnam to learn and apply this method to your fishing vessels, ensuring long-term safety and efficiency.

1.1 Enhance Durability and Load Capacity

- A proper splice maximizes the tensile strength of 8-strand ropes.

- It minimizes twisting, fraying, or premature breakage.

- For fishing boats frequently operating offshore, this is vital to ensure safe voyages.

1.2 Reduce the Risk of Slippage in Rough Seas

- Incorrect splicing can cause rope ends to slip under heavy loads.

- A correct 8-strand rope splicing technique ensures secure anchoring and minimizes the chance of mid-sea incidents.

1.3 Save on Maintenance and Replacement Costs

- Well-spliced ropes extend their service life significantly.

- Fishermen can reduce frequent rope replacements, cutting operational costs.

1.4 Meet Fishing Safety Standards

- Properly executed splices give fishermen greater confidence at sea.

- They also comply with safety requirements in aquaculture and commercial fishing.

- This reduces the risk of accidents and improves vessel stability.

2.1 High-Quality 8-Strand Rope

- Choose ropes suitable for the vessel’s load capacity, typically PP, PE, or Polyester.

- Inspect ropes carefully to ensure they are not frayed, damaged, or worn.

- Rope cutting knife or scissors: to trim rope ends neatly and prevent fraying.

- Splicing needle or fid: for threading rope strands accurately and securely.

- Protective gloves: to safeguard hands during handling.

- Tape or binding cord: to hold rope ends firmly in place while splicing.

2.3 Workspace & Setup

- Select a clean, flat surface for spreading out the rope.

- Use a workbench or support stand to control the rope more easily, minimizing tangling and twisting.

2.4 Technical Check Before Splicing

- Review each step of the 8-strand rope splicing method before starting.

- Confirm all tools are ready, the rope is untwisted, and its length is sufficient for your vessel’s needs.

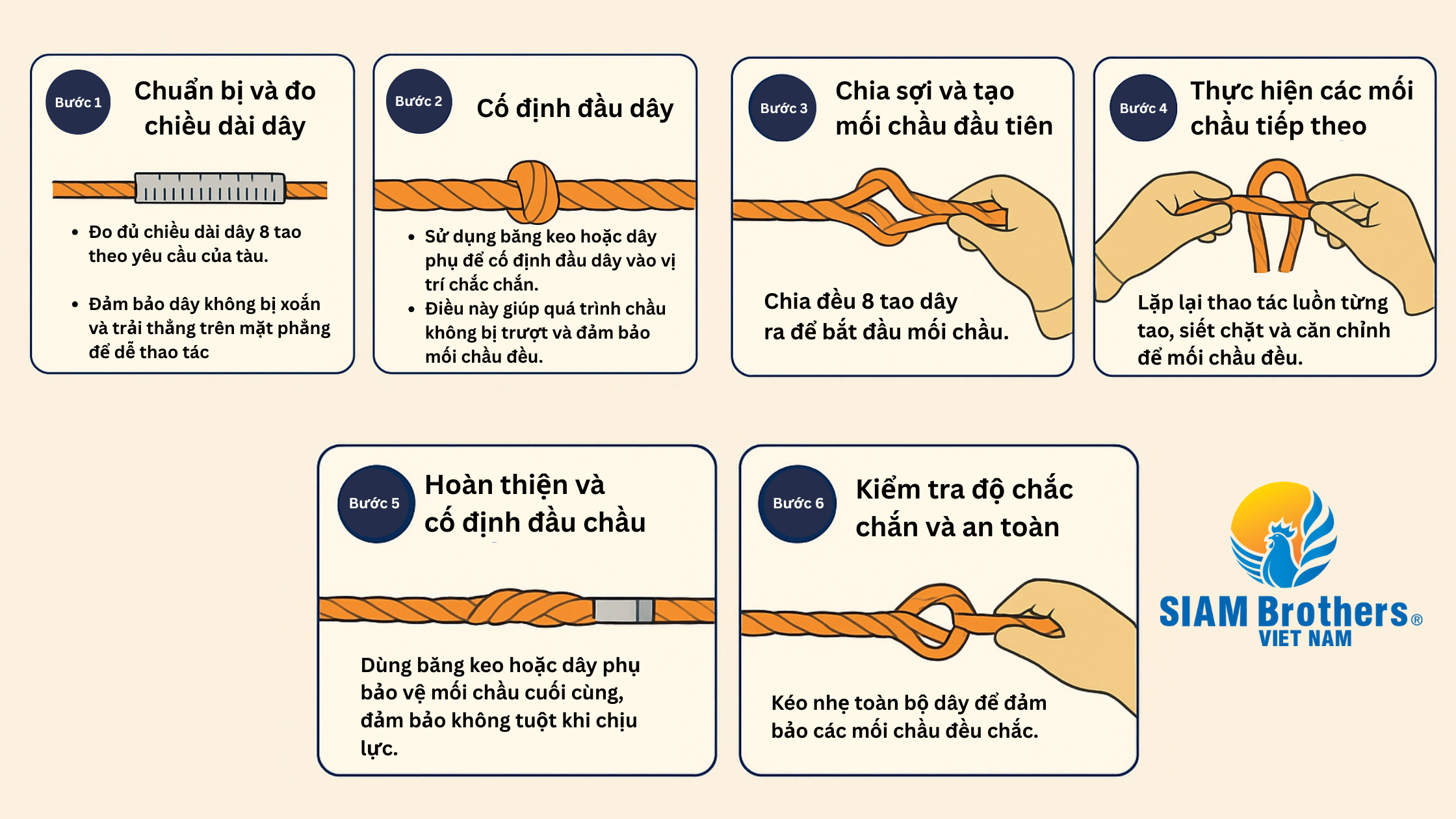

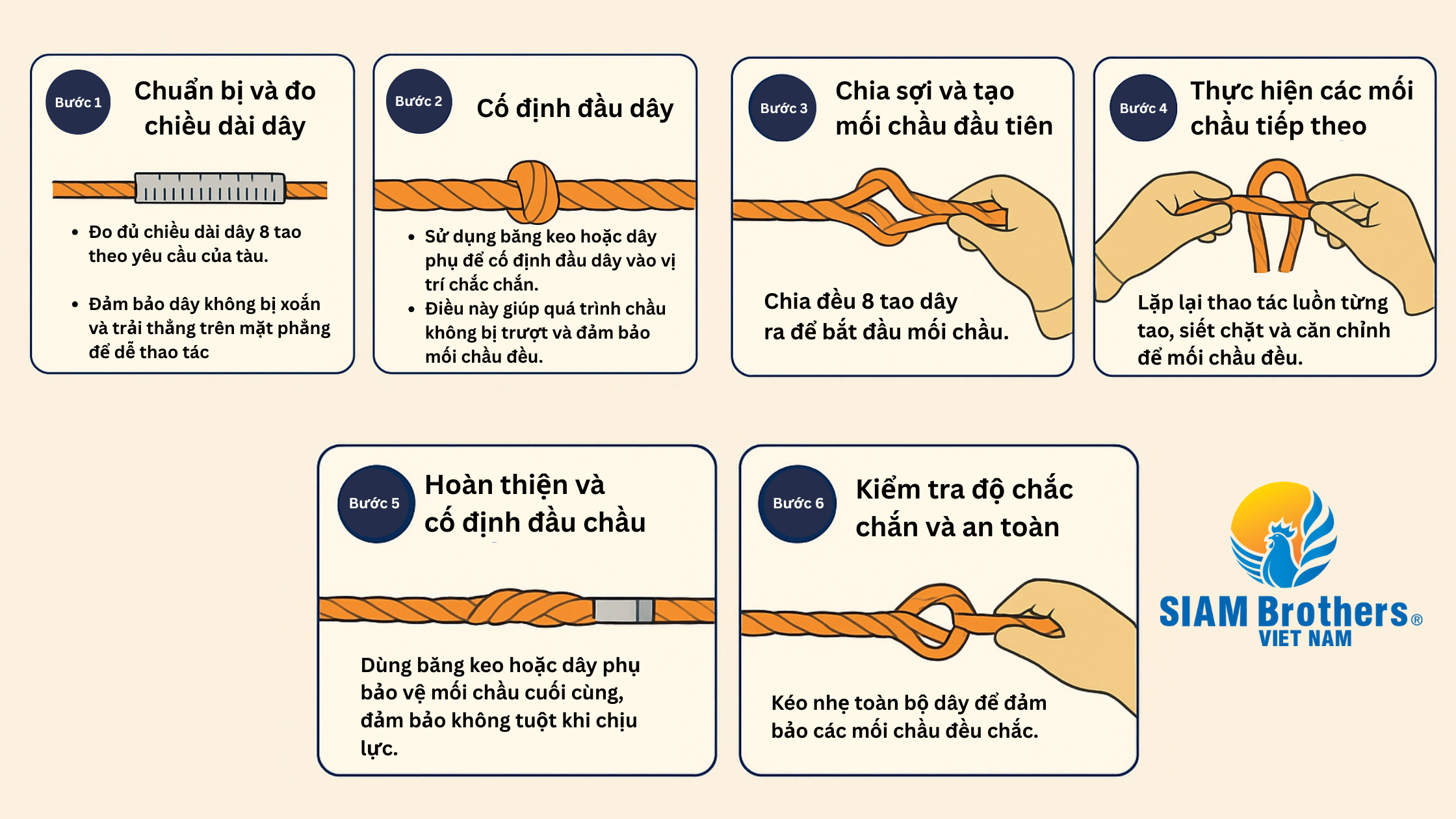

3. Step-by-Step Guide to 8-Strand Rope Splicing

Performing 8-strand rope splicing correctly is crucial to ensure strong, safe, and load-bearing joints for fishing vessels.

Step 1 – Prepare and Measure Rope Length

- Measure the required length of the 8-strand rope according to vessel needs.

- Ensure the rope is straight, untwisted, and laid flat for easier handling.

- Check supporting tools such as splicing needle, gloves, and tape.

Step 2 – Secure the Rope End

- Use tape or an auxiliary cord to firmly secure the rope end in place.

- This prevents slipping and helps maintain consistent, even splicing.

Step 3 – Separate Strands & Create the First Splice

- Divide the 8 strands evenly before beginning.

- Thread each strand in sequence, tightening the first splice to form a strong foundation.

Step 4 – Continue Splicing

- Repeat the threading and tightening process strand by strand.

- Check after each splice to avoid twisting or misalignment.

Step 5 – Finish and Lock the Splice End

- Once the desired splice length is achieved, secure the rope end tightly.

- Wrap the final splice with tape or auxiliary cord to prevent slippage under load.

Step 6 – Check Strength and Safety

- Pull the entire rope gently to confirm splice tightness.

- Adjust any loose strands immediately before using the rope at sea.

4. Common Mistakes in 8-Strand Rope Splicing & How to Fix Them

Even experienced fishermen may encounter issues during 8-strand rope splicing. Identifying and correcting them promptly ensures durable splices, longer rope life, and vessel safety.

4.1 Twisted or Misaligned Splice

- Cause: Uneven strand separation or rushing the process.

- Fix: Thread each strand carefully, checking after every splice. If twisted, undo and redo from the start.

- Tip: Use a flat surface or rope stand for straighter, more even splicing.

4.2 Rope End Slipping After Splicing

- Cause: Poorly secured rope end or insufficient tightening.

- Fix: Secure rope ends with tape or cord before splicing; ensure each splice is tightened.

- Tip: Test-pull the rope gently after splicing to check for slippage.

4.3 Uneven or Frayed Splices

- Cause: Incorrect threading sequence or uneven tension.

- Fix: Work step by step, tightening evenly, and check rope tension regularly.

- Tip: Use a 8-strand rope splicing checklist during the process.

4.4 Worn or Damaged Rope Before Splicing

- Cause: Using old ropes with multiple trips or low-quality materials.

- Fix: Inspect ropes carefully; replace damaged ones.

- Tip: Choose high-quality 8-strand ropes from SIAM Brothers Vietnam to reduce risks and extend splice life.

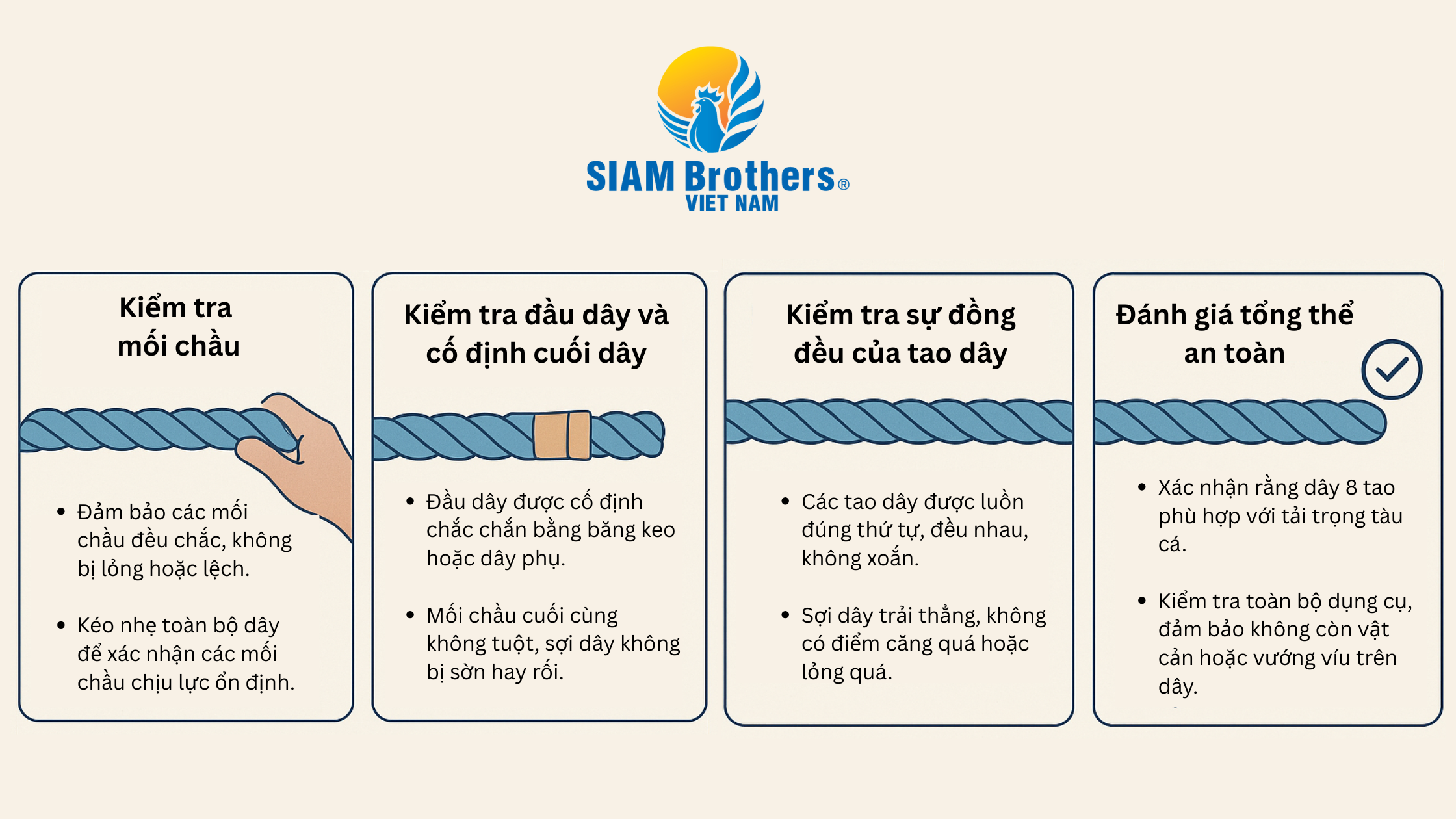

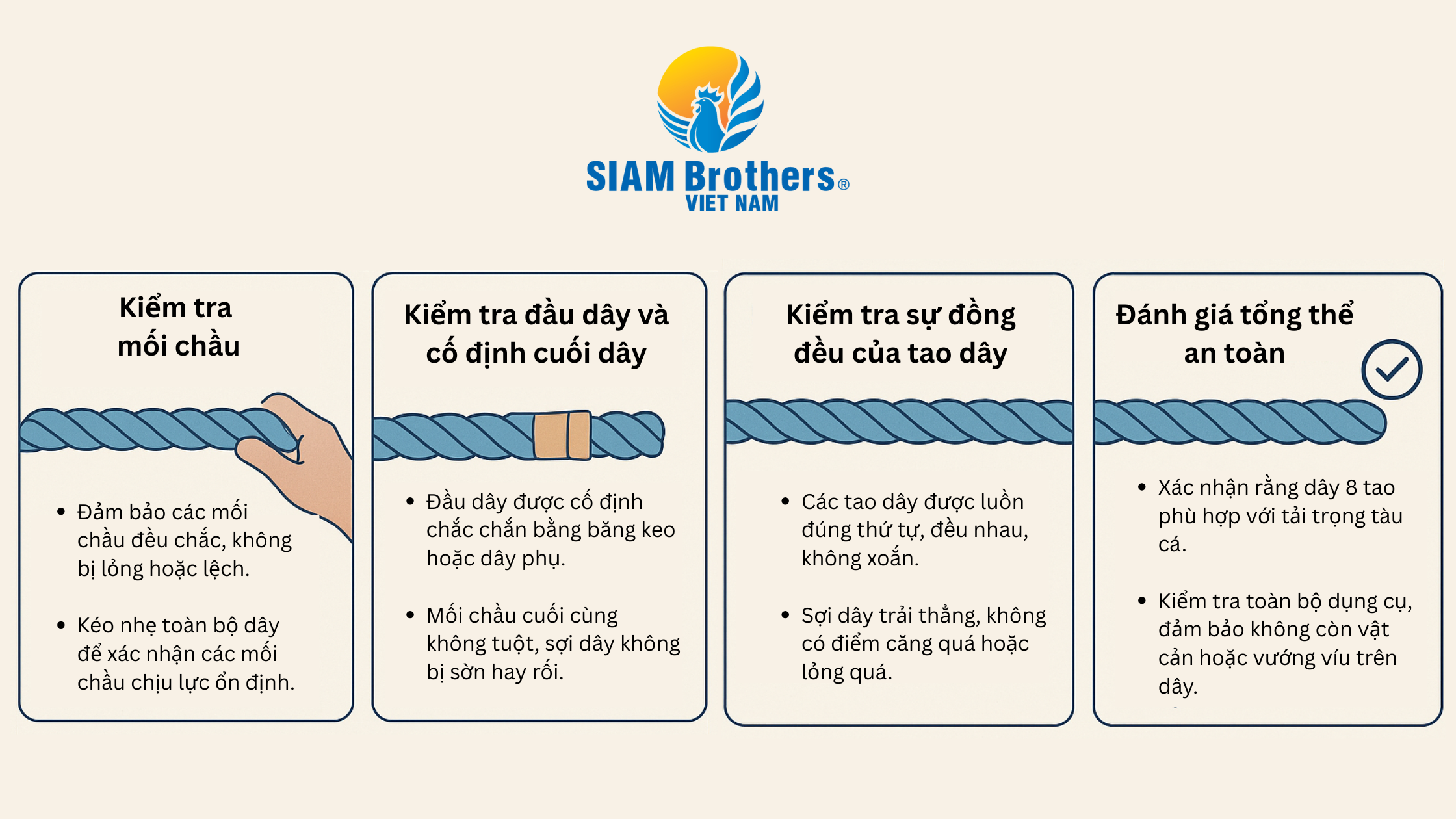

5. Quick Checklist Before Completing 8-Strand Rope Splicing

After finishing the 8-strand rope splicing process, reviewing the following ensures secure, reliable splices ready for fishing trips:

5.1 Splice Inspection

- All splices are tight, even, and aligned.

- Rope holds tension when lightly pulled.

5.2 Rope End & Final Locking

- Rope end secured with tape or auxiliary cord.

- Final splice intact, no fraying or tangling.

5.3 Strand Alignment

- Strands threaded in correct order, evenly spaced, and untwisted.

- Rope is straight, with no overly tight or loose sections.

5.4 Overall Safety Check

- Rope strength matches the vessel’s load capacity.

- No tools or objects left attached to the rope.

6. FAQ – Quick Answers About 8-Strand Rope Splicing

6.1 What are the advantages of 8-strand ropes compared to 3-strand or 4-strand ropes?

- Stronger load capacity: 8-strand ropes withstand heavy loads and abrasion better, making them ideal for long offshore trips.

- Secure splices: Reduce the risk of knots slipping in rough seas, enhancing vessel safety.

- Yes, as long as you follow the proper 8-strand rope splicing steps.

- Prepare the right tools, work on a flat surface, and double-check before using it on your vessel.

6.3 How often should I check my splices?

- Inspect splices before every fishing trip, especially after exposure to seawater or heavy loads.

- Regular checks help detect loose joints or worn strands early for timely adjustment.

6.4 Which type of 8-strand rope is best for fishing vessels?

- Choose high-quality PP, PE, or Polyester ropes with verified origins.

- Ropes from trusted suppliers like SIAM Brothers Vietnam extend splice life and reduce risks at sea.

6.5 Quick tips for better splicing

- Work step by step, slowly and carefully.

- Wear protective gloves for precision and safety.

- Use a checklist to ensure no steps are skipped.

6.6 How much 8-strand rope is needed for an average fishing vessel?

- The amount depends on vessel size and load capacity.

- Consult manufacturer guidelines or experienced technicians to determine the right rope length.

- Tools like splicing needles, gloves, scissors, and tape make the process easier and more accurate.

- It can be done manually, but it’s more time-consuming and error-prone.

6.8 Should I check new 8-strand ropes before splicing?

- Yes. Always inspect for frays, cuts, or twists before splicing.

- This ensures longer splice durability and safer performance at sea.

6.9 How do I fix a loose splice?

- Undo the loose splice and redo it following the standard 8-strand rope splicing steps.

- Tighten each strand evenly and check carefully for stability.

6.10 Which 8-strand ropes are most durable for fisheries?

- PP, PE, or Polyester ropes from trusted suppliers like SIAM Brothers Vietnam are the most reliable choice.

- They provide excellent durability, high load resistance, and cost savings on replacements.

Proper 8-strand rope splicing is the key to strong, long-lasting joints that ensure maximum safety for fishing vessels on every trip. By following the correct steps—from tool preparation, strand separation, to final inspection—you reduce rope slippage risks, save maintenance costs, and extend rope lifespan. Always use a quick checklist before setting sail to confirm splice stability. Start practicing today to experience improved safety and efficiency for your fishing operations.

Source: SIAM Brothers Vietnam

Contact us:

► Address: 5th floor, VRG Building, 177 Hai Ba Trung Street., Xuan Hoa Ward, Ho Chi Minh City, Vietnam

► Hotline: 1800 6129

► Tel: (+84) 28 38 912 889

► Email: info@sbg.vn

► Follow us for more details at: Facebook - Zalo OA - Tiktok - Youtube - LinkedIn

Download SBVN ID app here:

► CHPlay

► Appstore